About us

We facilitate the creation of strategy, design and implementation.

Our History

Established in 1919...

on the same area in the NORTH of MILANO, where it is now, the "BRENA GEARS" started its activity when the industrial economy was less developed than the agricultural one.

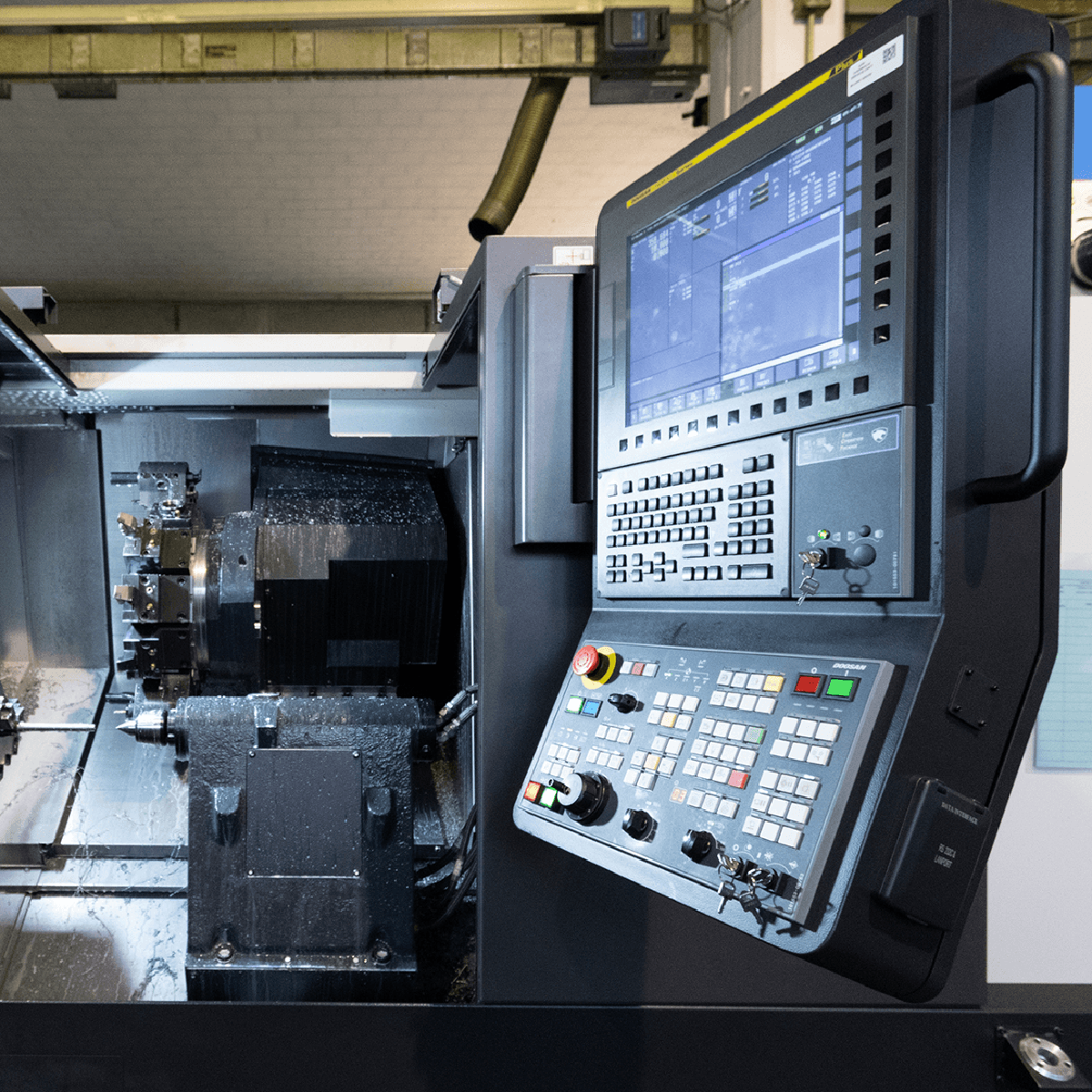

Still today the "BRENA Family" manages the firm, warranty of experience, continuous and technological innovation. The company whose premises cover a total surface of 7600 square meters, of 3700 of wich are built, owns the most recent existing machinary and equipment, manufacture and control tecnologies to make the one's products (general mechanical branch, gears, cutting, bevel gear, ecc.), able to satisfy the most various and particular requests of the customers.

In 2021 Brena Gears becomes part of the Colzani family. It is acquired by Colzani Group.

Our Products

Brena Gears...

owns acknowledged specialization into the production of mechanical aggregates und units at high technological contents to be used anywhere it is necessary to "transmit the motion"

All these parts are produced contemporaneously to satisfy the different requests of ther customers. The "BRENA GEARS" has been able to arrive at this aim, because it founded one's work abilities and made, inside the shop, different production area for each one of following market:

- Bevel gear

- Connecting, transmission, propeller shaft, splined shaft, driving and drived shaft

- Gears for gearbox and speed reducer

- Full units for 2WD and 4WD Racing car

- Full transmission for Helicopters

All these parts are produced contemporaneously to satisfy the different requests of ther customers. The "BRENA GEARS" has been able to arrive at this aim, because it founded one's work abilities and made, inside the shop, different production area for each one of following market:

- Aeronautic

- Automotive (racing and industrial)

- Motorcycle (racing and industrial)

- Marine (racing and industrial)

- Manufacture

Our Services

- Transmission gear calculation and design

- Collaboration with client's engineering dept. during the development phase

- Technical support throughout testing and approval of the products

- Regular control of satisfaction levels throughout product performance monitoring according to the most up-to-date Quality Assurance Methods

- Destructive and not destructive analysis of pieces (Magnaflux, Ultrasound test, ecc.)

- Manifacture of various materials (Steel, Titanium, Alluminium, Bronze alloy)

- Forging and respective heat treatment in neutral ambient and under vacuum

- Superficied layer and mass heat treatment (hardening, nitriding, hardening and tempering, case and pack hardeny, ecc.)

- Hardening under press

- Surface protection treatment (anodizing, cadmium plating, parkenzing, ecc.)

- Finishing operations (surface lapping, shot peening, ecc.)

- Laser welding

- Units and/or mechanical aggregates assembling

Our Certification

To grant compliance with the official functionality requirements of the products, we use:

- Certified and selected suppliers

- Documentation for each phase of the production proces

- ISO 9001: 2015 certification

- Certified and selected suppliers

- Documentation for each phase of the production proces

- ISO 9001: 2015 certification